how does a beam torque wrench work

The deflecting beam torque wrench applies the principle of adding torque to a deflecting beam rather than a coil spring. Usually split beam torque wrenches with 50 to 250 ft-lbs are used for industrial purposes.

Split Beam Torque Wrench How It Works

Theres nothing to set on it you just tighten the bolt and as you do you watch the.

. Herein how does beam torque wrench work. Beam wrenches have a rigid bar set between two fixed posts. A torque wrench uses a deflection beam or a calibrated spring system to find the amount of torque being applied to a nut or a bolt.

Clicker wrenches have a circular dial that clicks when you reach your desired torque value and stops turning once you reach the desired setting. Split beam torque wrenches tighten the nuts and bolts at precise torque value. This type of wrench is simple inherently accurate and inexpensive.

We try to answer the question how do torque wrenches work. Well the next question is how to use a beam torque wrench. Make sure the scale shows zero.

Lbs or Newton-meters Nm. How to Use a Torque Wrench. While this type of torque wrench prevents you from overtightening a fastener you cant see how much torque you have already applied.

By the action of the gear ratio of the multiplier the output torque is the one corresponding to the torque applied by the operator multiplied by the factor already considering the degree efficiency. These tools are designed this way. How does a beam type torque wrench work.

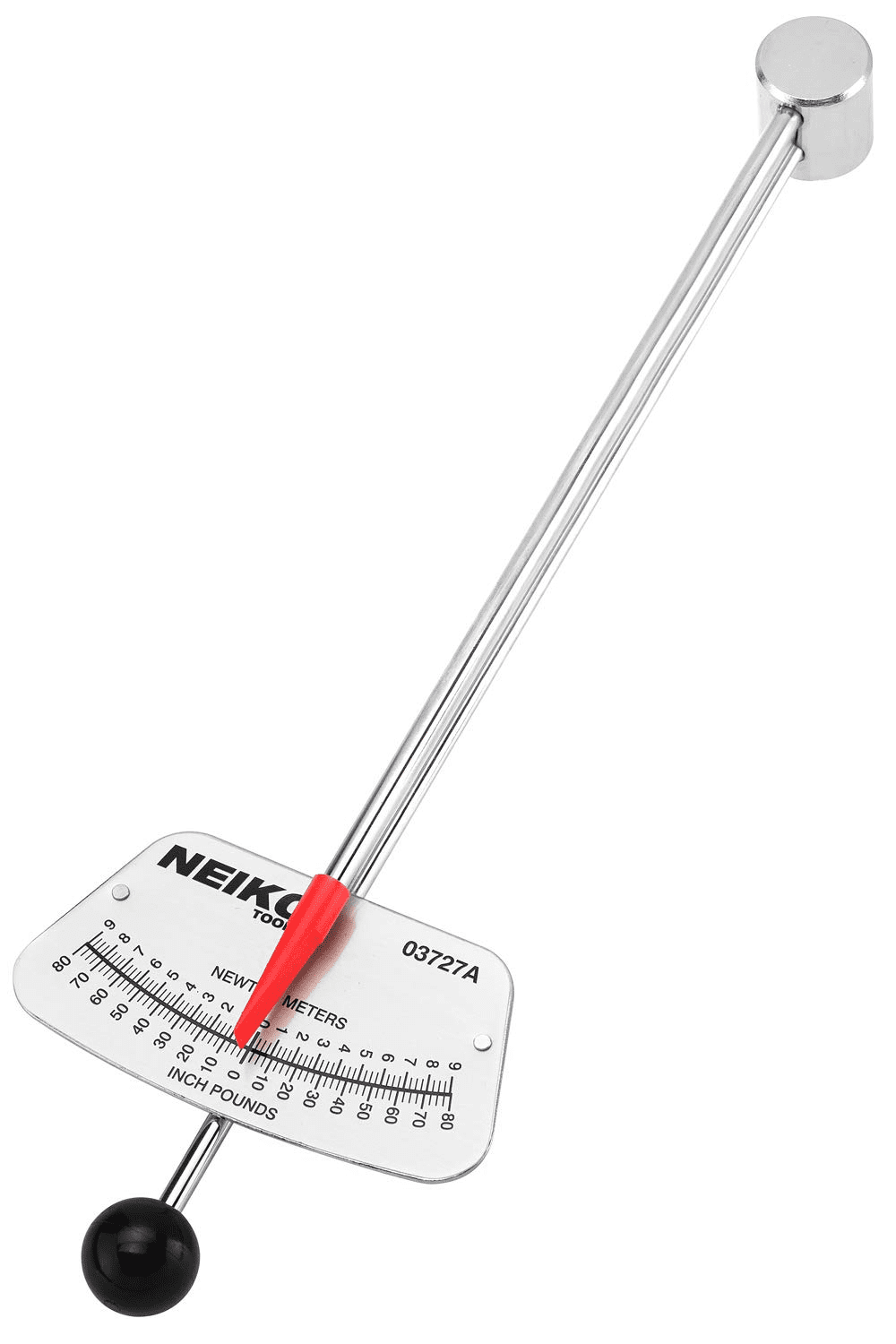

The torque wrench may display the torque being applied in foot-pounds ft. Thus the end of the indicating beam points to the magnitude of the torque that is currently being applied. Digital Style As the name implies digital torque wrenches have an.

As the wrench itself is twisted thats what torque means a twisting force the beam stays in place and the scale beneath the pointer moves to indicate the amount of twist or torque being applied. Input the desired torque level into the wrench scale. The wrench works by the beam being in line with zero on the scale.

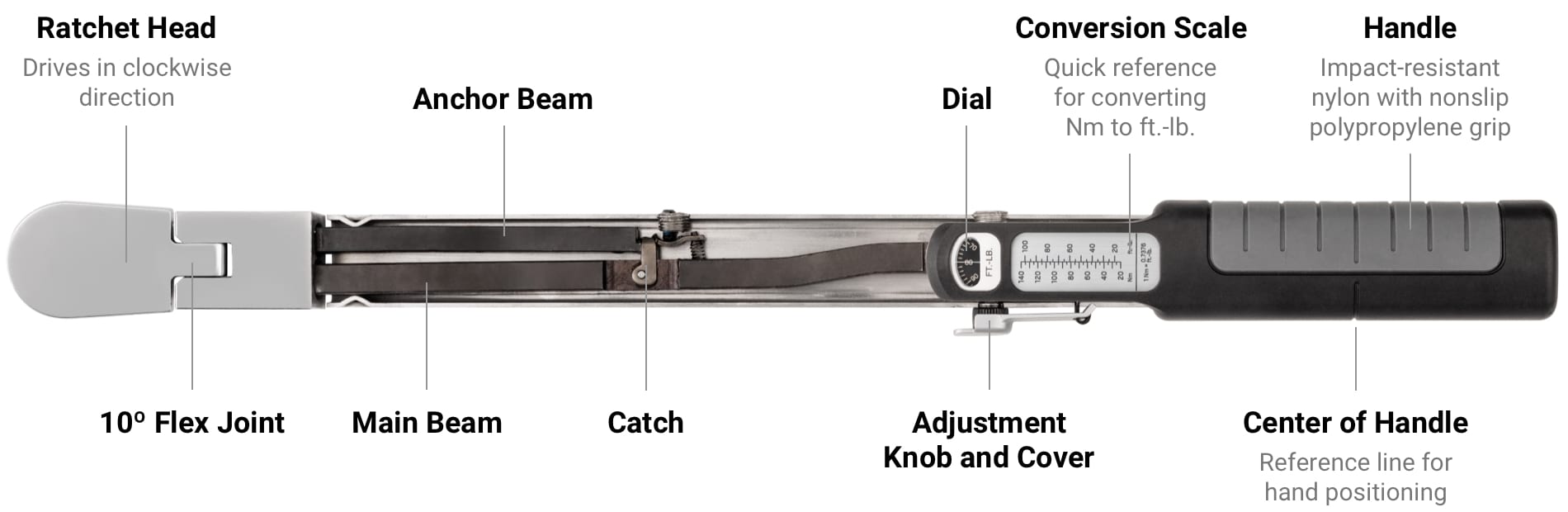

When the wrench is used to apply torque the lever bends and the indicating beam stays straight. The split beam torque wrenches work with two beams. Click to see full answer.

This type of wrench is simple inherently accurate and inexpensive. Only aligning the zero mark is required when calibrating a beam torque wrench. There are two simple steps to follow.

One of the simplest torque wrench is would be a beam style torque wrench. This value of torque is displayed on the associated meter or dial. This is achieved by moving the beam so that it lines up 3.

But whats important is that you position the socket with the bolt at the correct angle. It is used for factory settings tightness of nuts and bolts to provide the desired amount of torque. Beam torque wrenches are accurate to within 1-3 with the middle third of the range being closer to 1.

Line up the vertical line on the handle of your wrench with the vertical line above each number on the micrometer to reach your desired setting. They are simple durable and affordable. Remember always to consult the manufacturers instructions as applying too much torque can damage the bolt or.

One acts as a handle that deflects predictably when one turns it. Set the wrench for the precise torque youre seeking. There are two main types of torque wrenches clicker and beam.

Attach the socket to your torque wrench by pressing the square end of the socket onto the drive of the torque wrench. Through a torque wrench the operator manually applies a known torque at the input of the multiplier. It helps extend the accuracy of the tool longer that is safe even on maximum loading.

Set the wrench aside and hand tighten the nut or bolt that will be torqued as much as possible. When applying torque adjust the scale at zero and then preset the desired torque value. We look at Beam split beam digital and click style torque wrenchesBecome a Supporterwwwpatreo.

This causes the scale to move under the pointer. This wrench type uses a long beam attached to the head as a plumb line and scales on the handle below it. The drive is the square metal peg located on one end of the torque wrench.

One acts as a pointer beam that indicates the torque readings on the scale and the other acts as the handle that deflect when applying the pressure. How does a beam torque wrench work. Can You Calibrate A Split Beam Torque Wrench.

The pointer beam will start moving on the scale. Do you know about How Does A Torque Wrench Work. Beam torque wrenches bend a little while applying torque and its fine.

As mentioned using a beam torque wrench is simple and easy. For example if your main scale is slightly above the 90-ft. Slip Style This torque wrench works by losing its grip after reaching the set number of foot-pounds you have indicated that you want.

The handle is designed in such a way that it flexes slightly as the number of torque increases. A pointer beam is attached to the wrench head. When the wrench is used to apply torque the lever bends and the indicating beam stays straight.

A split beam torque wrench is a subcategory of beam wrench. Anyways split beams have two beams. The tool provides accurate reading and produces a clicking sound if it reached the tightness required.

You turn the handle to set the pressure as indicated on the scale. Positioning the socket in the wrong direction or angle can damage not only the bolts head but also the socket connector. 11 Step 1- Pick a torque wrench that calibrated 12 Step 2- Ensure about the types and purchase what you need 13 Step 3- Use clean and undamaged nuts and bolts 14 Step 4- Tighten the bolts on the threads 15 Step 5- Hold the handle of the wrench 16 Step 6- Attach the wrench straight in position so that you can read the beam.

And the other part gives out the reading. Thus the end of the indicating beam points to the magnitude of the torque that is currently being applied. A torque wrench is a tool that measures how much pressure you are applying to a bolt or nut.

The best split beam torque wrenches are accurate to up to 2.

How To Use A Beam Style Torque Wrench Wrench Guide

What To Consider When Shopping For A New Beam Torque Wrench

Split Beam Torque Wrench How It Works

Best Practices For Torque Wrench Repair

Presa 3 8 In Drive 0 Ft Lbs To 80 Ft Lbs Beam Style Torque Wrench Ps00600

File Split Beam Clicker Torque Concept Png Wikimedia Commons

Olsa Tools Split Beam Torque Wrench Youtube

How To Apply A Torque Wrench Youtube

Performance Tool W3001c 1 2 In Drive Beam Style Torque Wrench 0 150 Ft Lb For Sale Online Ebay

Split Beam Torque Wrench How It Works

The Best Beam Torque Wrenches Of 2021 Toolsdaddy Com

Precision Matters How To Use A Torque Wrench The Right Way

Tw 1 2 Beam Type Torque Wrench 0 14 Nm Park Tool

3 8 1 2 Inch Drive Split Beam Torque Wrench Set 2 Piece Trq99902 Tekton

Snap On Tqfr100b 3 8 Flex Head Split Beam Torque Wrench Review Youtube

1 4 Inch Drive Inch Pound Beam Type Torque Wrench Walmart Com

Deflecting Beam Torque Wrench Review Comparison Youtube

The Best Beam Type Torque Wrench For Low Torque Fasteners Floorjacked